- Typical fluidized bed coating line

- Case Studies

- Home >> Typical fluidized bed coating line >> Roll mesh PVC coating line

Roll mesh PVC coating line

Pre-heating furnace

Fluidized bed

Roll mesh fluidized bed coating

Steel coil mesh PVC coating line

Mesh de-coiler

Fence mesh powder coating line

Description of auto continous powder coating line:

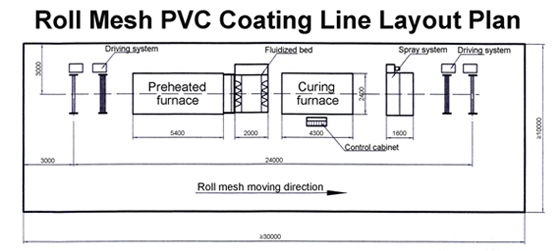

Your products need to be coated: Electrowelded galvanized mesh coils ; Application of finished products: fence system for highway, railway & industrial factory; Max. size of workpiece: Length: 30000mm × Width: 2500mm; Output: ≥3-5m/min; Heating source: electricity; Power consumption: installed capacity 170kw, average power 150kw; Water consumption: 2.5-3.0m3/h (circulated water); Powder application method: auto application by fluidized bed; Required size of coating factory: 30×10×5m(L×W×H)

Process flow: ①Manual feeding mesh coil on our de-coiler → ②Pre-heating furnace → ③Auto powder coating in fluidized bed → ④Curing furnace → ⑤Water cooling on coated mesh → ⑥Manual discharging of finished coil → ⑦Manual shaping correction → ⑧Quality control → ⑨Final package

Brief description: The metal fence is first preheated to a certain temperature and then passed through a fluidized bed of plastic powder where the powder particles melt, adhere and flow out to form a smooth continuous PVC coating. It is then post-heated to complete the curing of the outer surfaces. Both pre-heating furnace and curing furnace are natural gas heated.

Equipment list

1. Auto eletrical pre-heating & curing furnace

1.1 Pre-heating furnace:

Outer dimension (L×W×H): 5400×2540×1510(mm); Thermal insulating layer thickness: 200mm (mineral wool); Constructional material: Iron plate (1.5mm & 3.5mm), framework: angle steel (3#, 4# & 5#); Design heat-insulating property: ≤400℃

1.2 Curing furnace

Outer dimensions (L×W×H): 4300×2880×1980(mm); Thermal insulating layer thickness: 180mm (mineral wool); Constructional material: Iron plate (1.5mm & 2.0mm), framework: angle steel (3#, 4# & 5#); Constructional method: After machine-shaping, above-mentioned constructional material are pieced together by welding with the help of self-plugging rivet and bolt.; Design heat-insulating property: ≤300℃

1.3. Electrical heating equipment for pre-heating furnace

1.4 Electrical heating equipment for curing furnace

2. Fluidized bed, vibration generator

2.1 Fluidized bed

Outer dimensions (L×W×H): 2900×800×1200(mm);Constructional material: Iron plate (1.5mm & 2.0mm), 40×60 square steel tube, 4# angle steel, bolt and matched filter fabric;Constructional method: After machine-shaping, above-mentioned constructional material are pieced together by welding with the help of bolt.

2.2 Vibration generator:

Constructional material: 10mm Iron plate, framework: 5# angle steel, 5# channel steel, and mechanical part. Constructional method: After machine-shaping, above-mentioned constructional material are pieced together by welding with the help of bolt.

2.4 Dust removing device

2.5 Spray device

3. Roll mesh delivery system

4. Mesh de-coiler

5. Power supply control equipment, auto program control

Layout Plan of Roll Mesh PVC Coating Line:

Typical PVC Coated Roll Mesh:

Finished PVC coated coil mesh

Powder coated mesh

Mesh before PVC coated process

PVC coated roll mesh